La certificazione CE ATEX (ATmosphere EXplosive) regolamenta le apparecchiature destinate all’impiego in zone a rischio di esplosione nel mercato della Comunità Europea.

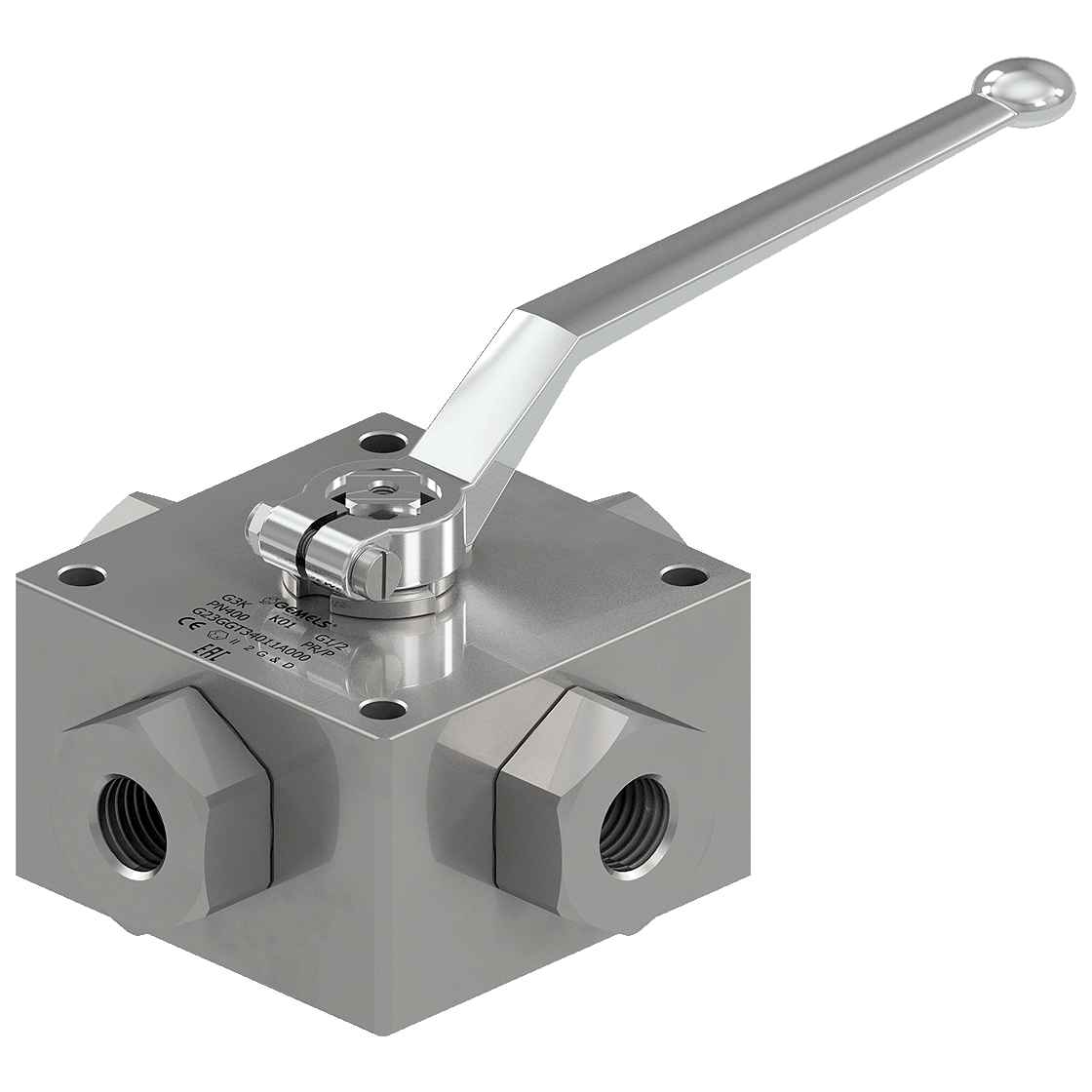

| POS | Description | Q.ty | Carbon Steel | Stainless Steel |

|---|---|---|---|---|

| 1 | Body | 1 | 1,0737 | |

| 2 | Adapter | 3 | 1,0737 | |

| 3 | Close adapter | 1 | 1,0737 | |

| 4 | Stemball adapter | 1 | 1,0737 | |

| 5 | Ball seat | 4 | POM | |

| 6 | Ball stem | 1 | 1,0737 | |

| 7 | Handle | 1 | ZINC | |

| 8 | Washer | 1 | 1,0116 | |

| 9 | Washer | 1 | 1,0116 | |

| 10 | Stemball ring | 2 | PTFE | |

| 11 | Pin | 1 | 1,0737 | |

| 12 | Body ring | 2 | PTFE | |

| 13 | Seeger | 1 | 1,4301 | |

| 14 | Stemball o-ring | 2 | NBR | |

| 15 | Body o-ring | 1 | NBR | |

| 16 | Adapter o-ring | 4 | NBR | |

| 17 | Seal o-ring | 4 | NBR | |

| 18 | Screw | 1 | DIN 6921 8.8 | |

| 19 | Caps | 4 | PVC |

| Item code | Tipo | DN | INCH | PN MPa | A mm | ⌀A mm | ⌀A/QC mm | B mm | ⌀B mm | B1 mm | b mm | C mm | C-BSPP | C RF mm | C RTJ mm | C1 mm | Cavity L mm | Cavity L1 mm | C-D | ch mm | CH1 mm | CS | D mm | D1 mm | d mm | ⌀d mm | ØD mm | ⌀d/QC mm | E mm | ⌀E mm | ⌀E linea mm | E1 mm | E2 mm | E3 mm | E4 mm | E5 mm | E6 mm | E7 mm | E8 mm | E9 mm | ES.V mm | F mm | F1 mm | Flow max l/min | Flow min-max l/min | G mm | ⌀G mm | ⌀G* mm | G1 mm | H mm | ⌀H mm | H1 mm | I mm | I1 mm | ISO5211 | J mm | K mm | ⌀K mm | ⌀K* mm | n°⌀K mm | ⌀K1 mm | L mm | L1 mm | L2 mm | L3 mm | L4 mm | LSCH80 mm | ⌀LW mm | ⌀LW1 mm | M mm | ⌀M mm | ØM1 mm | N mm | ⌀N mm | O-ring | P mm | ⌀P mm | Pilot Ratio | Pressure cracking MPa | Pressure max MPa | Pressure max peak MPa | Pressure max rotating MPa | Pressure max static MPa | Pressure max woking MPa | Q mm | ⌀Q mm | R mm | ⌀R mm | ⌀RA mm | S mm | ⌀S mm | Setting range MPa | Setting standard MPa | SW mm | SW1 mm | T mm | ⌀T mm | U mm | V mm | V1 - V2 C1 - C2GAS - MET | W mm | W* mm | W1 mm | W2 mm | Weight kg | X mm | X* mm | ⌀X mm | X1 mm | X-BSPP | Y mm | ⌀Y mm | Y1 mm | ⌀z mm | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| G23GGT15011A000 | G3K G 1/4 | 6 | 50 | 42 | 21.5 | 100 | 70 | 11 | 56.5 | 110 | 97.5 | 6.5 | 6 | G 1/4 | 9 | 1.767 | 55 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| G23NNT15011A000 | G3K N 1/4 | 6 | 50 | 42 | 21.5 | 100 | 70 | 11 | 56.5 | 110 | 97.5 | 6.5 | 6 | N 1/4 | 9 | 1.767 | 55 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| G23GGT25011A000 | G3K G 3/8 | 10 | 50 | 53 | 28.5 | 115 | 80 | 14 | 71.5 | 180 | 101 | 6.5 | 10 | G 3/8 | 14 | 3.018 | 65 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| G23NNT25011A000 | G3K N 3/8 | 10 | 50 | 53 | 28.5 | 115 | 80 | 14 | 71.5 | 180 | 101 | 6.5 | 10 | N 3/8 | 14 | 3.018 | 65 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| G23GGT34011A000 | G3K G 1/2 | 13 | 40 | 62 | 33 | 136 | 100 | 14 | 80.5 | 180 | 110 | 8.5 | 13 | G 1/2 | 14 | 5.247 | 80 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| G23NNT34011A000 | G3K N 1/2 | 13 | 40 | 62 | 33 | 136 | 100 | 14 | 80.5 | 180 | 110 | 8.5 | 13 | N 1/2 | 14 | 5.247 | 80 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| G23GGT43011A000 | G3K G 3/4 | 19 | 35 | 68 | 36 | 156 | 113 | 14 | 86.5 | 300 | 116.5 | 8.5 | 20 | G 3/4 | 14 | 6.898 | 85 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| G23NNT43011A000 | G3K N 3/4 | 19 | 35 | 68 | 36 | 156 | 113 | 14 | 86.5 | 300 | 116.5 | 8.5 | 20 | N 3/4 | 14 | 6.898 | 85 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| G23GGT53011A000 | G3K G 1 | 23 | 35 | 82 | 47.5 | 181 | 118 | 14 | 100.5 | 138 | 300 | 130.5 | 8.5 | 25 | G 1 | 14 | 9.005 | 85 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| G23GGR63011A000 | G3K G 1 1/4 R | 23 | 35 | 82 | 47.5 | 181 | 118 | 14 | 100.5 | 138 | 300 | 130.5 | 8.5 | 25 | G 1 1/4 | 14 | 8.989 | 85 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| G23GGR73011A000 | G3K G 1 1/2 R | 23 | 35 | 82 | 47.5 | 181 | 118 | 14 | 100.5 | 138 | 300 | 130.5 | 8.5 | 25 | G 1 1/2 | 14 | 9.213 | 85 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| G23NNT53011A000 | G3K N 1 | 23 | 35 | 82 | 47.5 | 181 | 118 | 14 | 100.5 | 138 | 300 | 130.5 | 8.5 | 25 | N 1 | 14 | 9.005 | 85 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| G23NNR63011A000 | G3K N 1 1/4 R | 23 | 35 | 82 | 47.5 | 181 | 118 | 14 | 100.5 | 138 | 300 | 130.5 | 8.5 | 25 | N 1 1/4 | 14 | 8.989 | 85 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| G23NNR73011A000 | G3K N 1 1/2 R | 23 | 35 | 82 | 47.5 | 181 | 118 | 14 | 100.5 | 138 | 300 | 130.5 | 8.5 | 25 | N 1 1/2 | 14 | 9.213 | 85 |

| Item code | Tipo | DN | INCH | PN MPa | A mm | ⌀A mm | ⌀A/QC mm | B mm | ⌀B mm | B1 mm | b mm | C mm | C-BSPP | C RF mm | C RTJ mm | C1 mm | Cavity L mm | Cavity L1 mm | C-D | ch mm | CH1 mm | CS | D mm | D1 mm | d mm | ⌀d mm | ØD mm | ⌀d/QC mm | E mm | ⌀E mm | ⌀E linea mm | E1 mm | E2 mm | E3 mm | E4 mm | E5 mm | E6 mm | E7 mm | E8 mm | E9 mm | ES.V mm | F mm | F1 mm | Flow max l/min | Flow min-max l/min | G mm | ⌀G mm | ⌀G* mm | G1 mm | H mm | ⌀H mm | H1 mm | I mm | I1 mm | ISO5211 | J mm | K mm | ⌀K mm | ⌀K* mm | n°⌀K mm | ⌀K1 mm | L mm | L1 mm | L2 mm | L3 mm | L4 mm | LSCH80 mm | ⌀LW mm | ⌀LW1 mm | M mm | ⌀M mm | ØM1 mm | N mm | ⌀N mm | O-ring | P mm | ⌀P mm | Pilot Ratio | Pressure cracking MPa | Pressure max MPa | Pressure max peak MPa | Pressure max rotating MPa | Pressure max static MPa | Pressure max woking MPa | Q mm | ⌀Q mm | R mm | ⌀R mm | ⌀RA mm | S mm | ⌀S mm | Setting range MPa | Setting standard MPa | SW mm | SW1 mm | T mm | ⌀T mm | U mm | V mm | V1 - V2 C1 - C2GAS - MET | W mm | W* mm | W1 mm | W2 mm | Weight kg | X mm | X* mm | ⌀X mm | X1 mm | X-BSPP | Y mm | ⌀Y mm | Y1 mm | ⌀z mm | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| G2AGGT15011A000 | G3K G 1/4 | 6 | 50 | 42 | 21.5 | 100 | 70 | 11 | 56.5 | 110 | 97.5 | 6.5 | 6 | G 1/4 | 9 | 1.767 | 55 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| G2ANNT15011A000 | G3K N 1/4 | 6 | 50 | 42 | 21.5 | 100 | 70 | 11 | 56.5 | 110 | 97.5 | 6.5 | 6 | N 1/4 | 9 | 1.767 | 55 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| G2AGGT25011A000 | G3K G 3/8 | 10 | 50 | 53 | 28.5 | 115 | 80 | 14 | 71.5 | 180 | 101 | 6.5 | 10 | G 3/8 | 14 | 3.018 | 65 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| G2ANNT25011A000 | G3K N 3/8 | 10 | 50 | 53 | 28.5 | 115 | 80 | 14 | 71.5 | 180 | 101 | 6.5 | 10 | N 3/8 | 14 | 3.018 | 65 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| G2AGGT34011A000 | G3K G 1/2 | 13 | 40 | 62 | 33 | 136 | 100 | 14 | 80.5 | 180 | 110 | 8.5 | 13 | G 1/2 | 14 | 5.247 | 80 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| G2ANNT34011A000 | G3K N 1/2 | 13 | 40 | 62 | 33 | 136 | 100 | 14 | 80.5 | 180 | 110 | 8.5 | 13 | N 1/2 | 14 | 5.247 | 80 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| G2AGGT43011A000 | G3K G 3/4 | 19 | 35 | 68 | 36 | 156 | 113 | 14 | 86.5 | 300 | 116.5 | 8.5 | 20 | G 3/4 | 14 | 6.898 | 85 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| G2ANNT43011A000 | G3K N 3/4 | 19 | 35 | 68 | 36 | 156 | 113 | 14 | 86.5 | 300 | 116.5 | 8.5 | 20 | N 3/4 | 14 | 6.898 | 85 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| G2AGGT53011A000 | G3K G 1 | 23 | 35 | 82 | 47.5 | 181 | 118 | 14 | 100.5 | 138 | 300 | 130.5 | 8.5 | 25 | G 1 | 14 | 9.005 | 85 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| G2AGGR63011A000 | G3K G 1 1/4 R | 23 | 35 | 82 | 47.5 | 181 | 118 | 14 | 100.5 | 138 | 300 | 130.5 | 8.5 | 25 | G 1 1/4 | 14 | 8.989 | 85 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| G2AGGR73011A000 | G3K G 1 1/2 R | 23 | 35 | 82 | 47.5 | 181 | 118 | 14 | 100.5 | 138 | 300 | 130.5 | 8.5 | 25 | G 1 1/2 | 14 | 9.213 | 85 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| G2ANNT53011A000 | G3K N 1 | 23 | 35 | 82 | 47.5 | 181 | 118 | 14 | 100.5 | 138 | 300 | 130.5 | 8.5 | 25 | N 1 | 14 | 9.005 | 85 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| G2ANNR63011A000 | G3K N 1 1/4 R | 23 | 35 | 82 | 47.5 | 181 | 118 | 14 | 100.5 | 138 | 300 | 130.5 | 8.5 | 25 | N 1 1/4 | 14 | 8.989 | 85 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| G2ANNR73011A000 | G3K N 1 1/2 R | 23 | 35 | 82 | 47.5 | 181 | 118 | 14 | 100.5 | 138 | 300 | 130.5 | 8.5 | 25 | N 1 1/2 | 14 | 9.213 | 85 |

| Item code | Tipo | DN | INCH | PN MPa | A mm | ⌀A mm | ⌀A/QC mm | B mm | ⌀B mm | B1 mm | b mm | C mm | C-BSPP | C RF mm | C RTJ mm | C1 mm | Cavity L mm | Cavity L1 mm | C-D | ch mm | CH1 mm | CS | D mm | D1 mm | d mm | ⌀d mm | ØD mm | ⌀d/QC mm | E mm | ⌀E mm | ⌀E linea mm | E1 mm | E2 mm | E3 mm | E4 mm | E5 mm | E6 mm | E7 mm | E8 mm | E9 mm | ES.V mm | F mm | F1 mm | Flow max l/min | Flow min-max l/min | G mm | ⌀G mm | ⌀G* mm | G1 mm | H mm | ⌀H mm | H1 mm | I mm | I1 mm | ISO5211 | J mm | K mm | ⌀K mm | ⌀K* mm | n°⌀K mm | ⌀K1 mm | L mm | L1 mm | L2 mm | L3 mm | L4 mm | LSCH80 mm | ⌀LW mm | ⌀LW1 mm | M mm | ⌀M mm | ØM1 mm | N mm | ⌀N mm | O-ring | P mm | ⌀P mm | Pilot Ratio | Pressure cracking MPa | Pressure max MPa | Pressure max peak MPa | Pressure max rotating MPa | Pressure max static MPa | Pressure max woking MPa | Q mm | ⌀Q mm | R mm | ⌀R mm | ⌀RA mm | S mm | ⌀S mm | Setting range MPa | Setting standard MPa | SW mm | SW1 mm | T mm | ⌀T mm | U mm | V mm | V1 - V2 C1 - C2GAS - MET | W mm | W* mm | W1 mm | W2 mm | Weight kg | X mm | X* mm | ⌀X mm | X1 mm | X-BSPP | Y mm | ⌀Y mm | Y1 mm | ⌀z mm | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| G2BGGT15011A000 | G3K G 1/4 | 5 | 50 | 42 | 21.5 | 100 | 70 | 11 | 56.5 | 110 | 97.5 | 6.5 | 6 | G 1/4 | 9 | 1.767 | 55 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| G2BNNT15011A000 | G3K N 1/4 | 5 | 50 | 42 | 21.5 | 100 | 70 | 11 | 56.5 | 110 | 97.5 | 6.5 | 6 | N 1/4 | 9 | 1.767 | 55 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| G2BGGT25011A000 | G3K G 3/8 | 7 | 50 | 53 | 28.5 | 115 | 80 | 14 | 71.5 | 180 | 101 | 6.5 | 10 | G 3/8 | 14 | 3.018 | 65 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| G2BNNT25011A000 | G3K N 3/8 | 7 | 50 | 53 | 28.5 | 115 | 80 | 14 | 71.5 | 180 | 101 | 6.5 | 10 | N 3/8 | 14 | 3.018 | 65 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| G2BGGT34011A000 | G3K G 1/2 | 10 | 40 | 62 | 33 | 136 | 100 | 14 | 80.5 | 180 | 110 | 8.5 | 13 | G 1/2 | 14 | 5.247 | 80 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| G2BNNT34011A000 | G3K N 1/2 | 10 | 40 | 62 | 33 | 136 | 100 | 14 | 80.5 | 180 | 110 | 8.5 | 13 | N 1/2 | 14 | 5.247 | 80 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| G2BGGT43011A000 | G3K G 3/4 | 15 | 35 | 68 | 36 | 156 | 113 | 14 | 86.5 | 300 | 116.5 | 8.5 | 20 | G 3/4 | 14 | 6.898 | 85 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| G2BNNT43011A000 | G3K N 3/4 | 15 | 35 | 68 | 36 | 156 | 113 | 14 | 86.5 | 300 | 116.5 | 8.5 | 20 | N 3/4 | 14 | 6.898 | 85 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| G2BGGT53011A000 | G3K G 1 | 17 | 35 | 82 | 47.5 | 181 | 118 | 14 | 100.5 | 138 | 300 | 130.5 | 8.5 | 25 | G 1 | 14 | 9.005 | 85 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| G2BGGR63011A000 | G3K G 1 1/4 R | 17 | 35 | 82 | 47.5 | 181 | 118 | 14 | 100.5 | 138 | 300 | 130.5 | 8.5 | 25 | G 1 1/4 | 14 | 8.989 | 85 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| G2BGGR73011A000 | G3K G 1 1/2 R | 17 | 35 | 82 | 47.5 | 181 | 118 | 14 | 100.5 | 138 | 300 | 130.5 | 8.5 | 25 | G 1 1/2 | 14 | 9.213 | 85 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| G2BNNT53011A000 | G3K N 1 | 17 | 35 | 82 | 47.5 | 181 | 118 | 14 | 100.5 | 138 | 300 | 130.5 | 8.5 | 25 | N 1 | 14 | 9.005 | 85 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| G2BNNR63011A000 | G3K N 1 1/4 R | 17 | 35 | 82 | 47.5 | 181 | 118 | 14 | 100.5 | 138 | 300 | 130.5 | 8.5 | 25 | N 1 1/4 | 14 | 8.989 | 85 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| G2BNNR73011A000 | G3K N 1 1/2 R | 17 | 35 | 82 | 47.5 | 181 | 118 | 14 | 100.5 | 138 | 300 | 130.5 | 8.5 | 25 | N 1 1/2 | 14 | 9.213 | 85 |

La certificazione CE ATEX (ATmosphere EXplosive) regolamenta le apparecchiature destinate all’impiego in zone a rischio di esplosione nel mercato della Comunità Europea.

La certificazione CE PED (Pressure Equipment Directive) regolamenta la progettazione, la costruzione, l’equipaggiamento e l’installazione in sicurezza di attrezzature in pressione nel mercato della Comunità Europea.

I certificati e le dichiarazioni EAC (EurAsian Conformity) attesta la conformità dei prodotti che siano stati considerati e valutati conformi ai regolamenti tecnici dell’unione Doganale euroasiatica, con particolare riferimento alle attrezzature in pressione, a quelle destinate ad atmosfere esplosive e alle macchine.

La certificazione UKCA Ex (UK Conformity Assessed EXplosive atmosphere) regolamenta le apparecchiature destinate all’impiego in zone a rischio di esplosione nel mercato del Regno Unito.

La certificazione UKCA PER (UK Conformity Assessed Pressure Equipment Regulation) regolamenta la progettazione, la costruzione, l’equipaggiamento e l’installazione in sicurezza di attrezzature in pressione nel mercato del Regno Unito.

"*" indica i campi obbligatori